Katherine Van Adzin: So, I’ve heard people say that when you’re starting out with the Last Planner® System, you have to learn it on sticky notes. You disagree—why?

Hal Macomber: Here’s the interesting thing about everybody who says, “Oh, you gotta start with analog before you start digital.” My first question is always, “Well, have you experimented by starting with digital first?”

They say, “No, you’ve gotta start with analog first.”

I say, “So you don’t know, then?”

The truth is that most of the people who are saying that you must start with an analog approach haven’t examined doing it any other way. Nobody is saying this because they’ve got good experience or bad experience. At a minimum, they should be doing all kinds of experiments on what’s working or what’s not working.

And they’re not. Some of the people who are most vociferous about this are the ones that have been doing it longest, and it is absolutely antithetical to Lean, the not experimenting. We do experiments for learning. They’re not experimenting; they’re not learning. And they should be experimenting with it.

KV: Why do you think starting with software is preferable?

HM: The first thing that you need to be successful in both analog and digital settings is someone who knows how to use the Last Planner® System. Somebody needs to know what they should be doing. If you have customers who don’t know the Last Planner® System and they didn’t get any outside help, then they’re likely not going to do some of the basic things. But if you have somebody who is a competent user of the Last Planner® System, then they can easily figure out how to use Touchplan.

For example, how do you make promises for the coming week’s work? Your tutorial videos show how that’s done. A cursory view of Touchplan allows them to pull plan, do their pull plan, make their promises, status their promises, and get their PPC. That can be handled with the simplest of support, and as long as there’s one person on the job who knows what a good Last Planner® System implementation looks like, all of that support is already there from the software. Visually you can look at it, and it’s simple to do.

KV: What do you think are the biggest challenges to teams starting out?

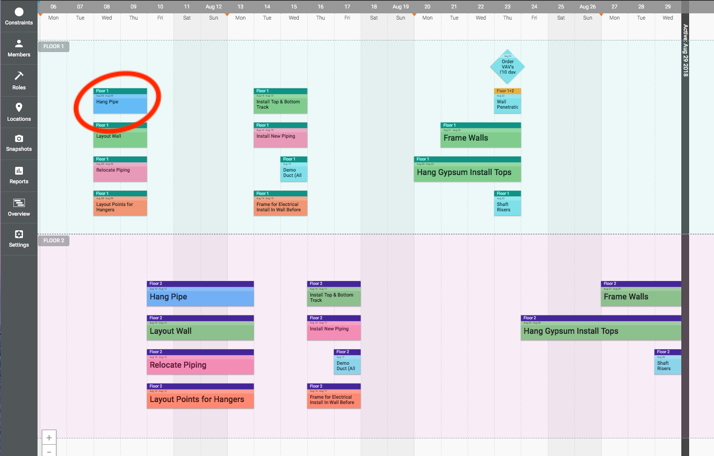

HM: I notice that teams create work activities that are too long. It’s customary in the typical “three-week look-ahead world” that whatever the work is that needs to be done, it takes a week to do it, just because that’s how they’ve planned for years. If you look at their CPM schedules or the superintendent’s look-ahead plan, they’ll just say, “Yeah, do this work in this one week, do this work in that one week.” It’s not down to the day. It just shows the week and it shows five days. So people think in five-day planning periods and they use five-day planning periods.

KV: How does Touchplan counteract that?

HM: Touchplan counteracts it by presenting a card with the default conditions of a two-person crew working for one day. The last planner has to go in and think differently. How long is it really going to take you? What’s the smallest crew that you’re using, and the least amount of time it takes to do this? Two people for one day or two people for two days or three people for one day or four people for one day? Touchplan gets people to think about this the right way from the outset.

KV: What tends to trip people up if they don’t start off digitally?

HM: One of the challenges that people have with pull planning on the wall versus in software is that the logic isn’t obvious. By logic, what I mean is that if I’m going to place concrete, there are four or five precedent actions that need to occur. The excavation, sub material, forming, reinforcing and then an inspection that all are good, because once you put concrete in place, if it wasn’t right now you have to take it all out. You can’t correct something that wasn’t right, because it’s concrete.

When you put this on the wall with stickies, that looks like a very simple linear process. The inspection happens before the placement, the rebar happens before the inspection, the forming happens before the rebar, and the under material happens before the forming.

But we have a lot of situations where you need two or more precedent activities that happen either concurrently or separated in different value streams or by time gaps. So how do you show this? You take your marker and you draw a line on the background paper. And that means “we need this particular sticky that’s happening in week two before we do this thing that happens in week five.” And everything else that happens, all the other precedent work that’s needed, also happens in week five. So you do this completely out of sync thing. Well, how do you handle this on sticky notes and the wall? You don’t.

KV: And how does that differ if you’re using software?

HM: Touchplan makes it easy to handle these outside-the-workflow precedent activities. You’re able to do something that you need to do, and that you can’t do with sticky notes, very easily with Touchplan. And you only do it by exception, because the inference in the placement of the stickies—if you have some sticky note on the right—is that anything to its immediate left is a required precedent activity. The logic is inferred by the placement. And you can’t show that on the wall, but electronically, that’s handled very well.

KV: I’ve heard people say that more experienced teams can jump into a digital tool right away, but that novice teams need the experience of stickies on a wall. What are your thoughts?

HM: What’s true is that if you’re going to successfully use the Last Planner® System, you need to know what that means. What does success look like? So in all cases, you need somebody who can help. You must have somebody who knows what it looks like when it’s happening. So it’s always easier if the team has experience. But one person on the team who is recognized as being knowledgeable is sufficient. Just let that person lead.

KV: I think a lot of people who are wary of starting teams on digital think that by doing that it means that you either don’t have meetings anymore or you don’t communicate face-to-face. Do you run into that misconception?

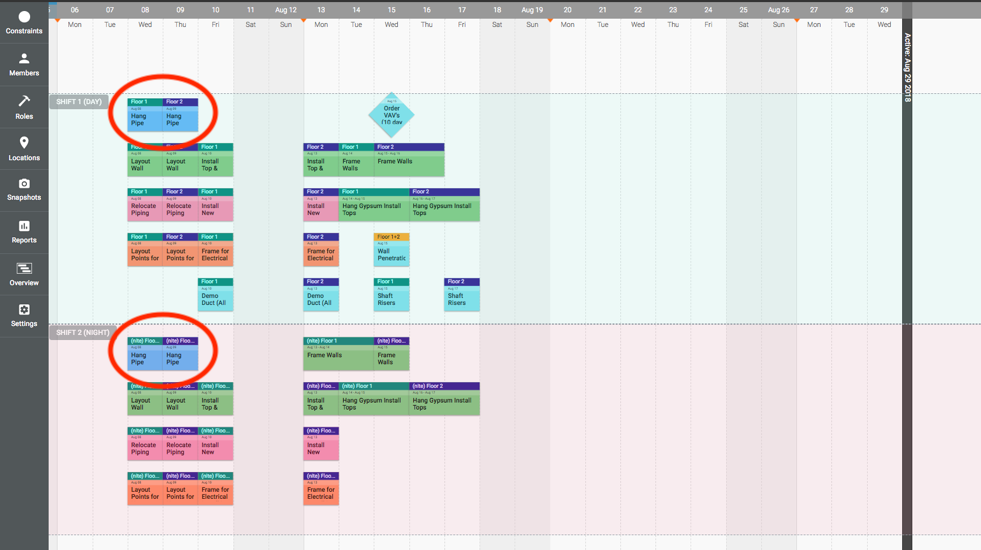

HM: It all boils down to the question of what we’re trying to do with the Last Planner® System. Last planners are the foremen, they’re the people who are assigning work and who have the ability to make promises for the completion of that work. Now what we’re trying to do is build the plan based on the people who assign work and can make promises. So if we’re pull planning, we’re designing a plan that can be Lean. We’re tapping into their knowledge of both the work and the people.

And the only way you can pull plan is with those people in the room. Now you could sit there and import a plan from a CPM schedule, but the last planners had nothing to do with it. It’s the superintendent’s plan. If you try to build the project off of that, then you haven’t included the thinking of the last planners, their expertise and judgment. You haven’t included that in the development of the pull plan.

Even when the team is in the room together, if the conversation isn’t well-facilitated, then they’re just doing a puzzle. They’re not having a conversation about how to create flow on their project. What’s the production approach that will create flow on our project? That’s the question that you start with. We’re here to establish a production approach that produces flow on our project for this sequence of work, to get to this milestone. What’s crucial is that there’s someone there acting like a facilitative leader so that you tap into the expertise and judgment of the last planners.

Now, it’s true that Touchplan doesn’t force you to have that. It’s a canvas. The interesting thing though is it’s a smart canvas, so when you do things in certain ways, it makes inferences of what you meant, which can’t be done on a wall.

KV: Can you expand on the role of the facilitator?

HM: Sure. It’s a very important role. Ask yourself, is the superintendent changing his or her behavior to be a facilitative leader, or do they continue in the director mode? When I see director behavior I stop it because we need a facilitator, not a director. It’s about changing the conversation between the people, and you need a facilitative leader to do that.

You also need to be clear on what you’re there to do. You’re designing a production approach for a phase of the work so that you can achieve flow. That’s what you’re there to do. And there are engineering principles that need to be followed, as well as the nature of the construction activities that need to be understood. It takes both of those. Most teams make a dramatic improvement in the pull plans done by the trades versus the production plans that are done by superintendents because they get a superior understanding of the nature of the construction work while the planning is going on. But they can be far superior once we introduce the engineering principles associated with good production system design.

KV: Aside from the facilitation, what other benefits do you see from digital planning?

HM: There are some very practical aspects of why your first weekly work plan needs to be digital. All the calculations are done for you. All statuses can be distributed. You don’t have to be chasing people around. They have tablets, they can tell you that they finished or they didn’t finish. Right off the bat, you have a far better chance that you’re going to get a good report on PPC. I don’t mean that it’s going to be high PPC, I mean it’s going to be an accurate reporting of what happened, and that you’re in a position to share that promptly and to improve on that.

So you’re in much better shape using software than spreadsheets, because spreadsheets are filled out by hand, they need to be collated, they need to be somehow updated and use some kind of math, either spreadsheets online so the math is done automatically for you, or you’re doing this offline.

The second thing that’s much easier right away is making improvements. Last planners’ first promises won’t be very accurate. At the outset, the last planners don’t understand enough about their work to get it right. Using Touchplan, you have a robust way of managing all of the re-planning that needs to happen. So, over the course of two to four weeks, the last planners learn as they move their work items around electronically, which can’t be done with sticky notes and spreadsheets.

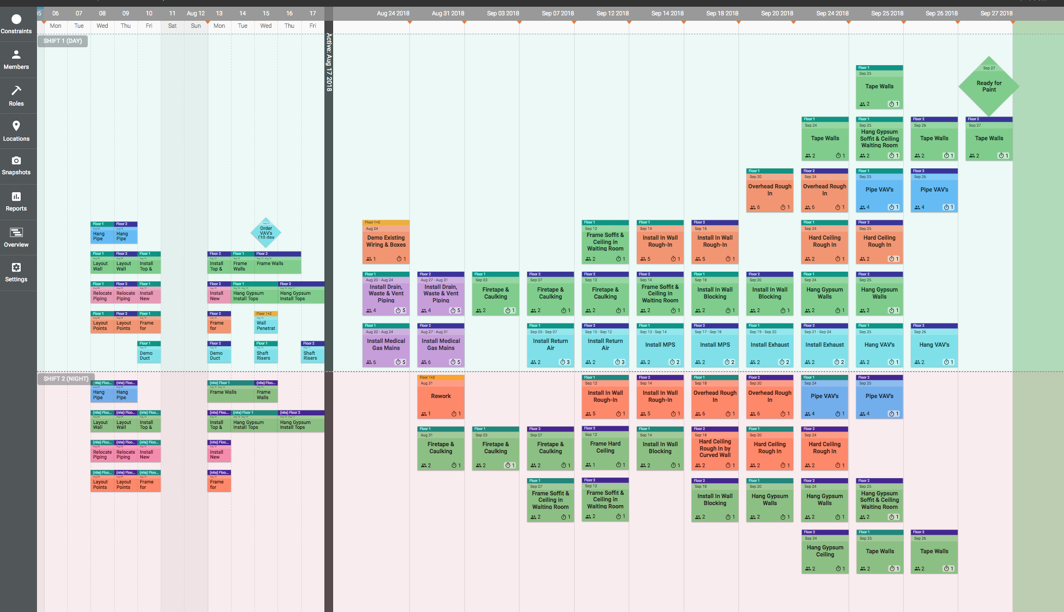

Third, there are a lot of people who don’t want to record PPC from the beginning. They want to see if they’ll get used to this Last Planner® thing first. But if they use the software, they can be better in week two than they were in week one, because they can see what they learned. Like, oh, look at this. All these plumbing, welding tasks took longer. Why did they take longer? We don’t know yet, but we know for next week to add an extra day across these tasks. Boom! Already the next week’s plan is better, even if they don’t understand why.

If you don’t have the data, you can’t improve right away. Touchplan immediately gives you the data. So from the beginning, you can make data-informed improvements from week two.

The team sees a visual indicator of what needs improvement. They don’t have to study the data. That’s so important. For example, look at all these red pins for plumbing. Let’s dive in and look at it. Oh my gosh, it’s all welding tasks. What are we going to do about it next week? Add another day across the board. Perfect. Improvement made.

KV: What are the differences you see in the way constraints are handled?

HM: In the analog world, constraints are handled independently of the sticky notes on a constraints log document. With Touchplan, you print a constraints log from a visual display of the constraints on the plan. And the constraints are linked to the activity that’s being constrained. So if I need a hot work permit to weld three days before I do the welding, that shows up on the plan, and if it’s not available three days before, then that welding activity all of a sudden turns a different color. So we see immediately that work that we should be doing is at risk of not happening. The whole team, not just the construction manager, is now in the position of seeing what needs attention, why, and what’s at risk. And that is absolutely not possible with stickies. Everybody using analog approaches is maintaining a constraints removal process completely separate from their plan.

KV: What else is different?

HM: Another key to making the Last Planner® System work is to shift the relationships of last planners to each other. We get high PPC and good flow when we have trade partner foremen treating each other as partners, as customers. How does software help this happen? The principal way is in the always-available visual display of the customer-performer relationships in the promise period. Nobody is able to do that when they’re analog. But if you start with digital, you get there in week one.

Another is latency of data, which I sometimes call friction. The latency in the analog approach makes the data less useful. Even when we get it, we’ve already gone on to different work.

So eliminating that latency makes the data much more valuable. It’s much more like driving with a dashboard. What you’re looking at on the dashboard is useful while you’re driving, as opposed to calculating the miles per gallon of the last 100 miles you’ve driven. The usefulness of data is dramatically diminished by the latency, and you don’t even get the data if you didn’t put in the administrative effort.

But with Touchplan, all that latency goes away. And you get the benefits from that on day one.

Going to LCI Congress 2018? Let’s meet.